Inventory management is the backbone of effective field service operations. For small FSM businesses and enterprise-level providers alike, having the right parts and tools available at the right time is crucial to completing jobs on the first visit.

In fact, first-time fix rates in field service average only ~77%, often due to missing or unavailable parts. Poor inventory management leads to delayed repairs, repeat visits, and frustrated customers – all of which hurt the bottom line.

Moreover, recent supply chain disruptions (experienced by 94% of Fortune 1000 companies) have led to frequent parts shortages, further complicating inventory planning for field service teams.

So, addressing the intricacies of this crucial aspect of the field has become a necessity in the current time. In this comprehensive guide, we’ll explore all aspects of field service inventory management, from understanding its core to addressing common challenges and key benefits, and directing you towards the right solution.

What is Field Service Inventory Management?

Field service inventory management involves planning, tracking, and controlling all the parts, tools, equipment, and materials that field technicians require to perform their jobs. This includes everything from replacement parts and consumable supplies to specialized tools and even vehicles. Essentially, it involves ensuring that the right parts and assets are in the right place at the right time to support field work.

Scope:

Unlike traditional inventory management, which might focus on a single warehouse or store, field service inventory is decentralized. Technicians often carry stock in their vans or trucks (“truck inventory”), and companies may have multiple depots or warehouses.

Inventory management for field service must account for multiple locations – central warehouses, regional depots, and mobile inventories on technicians’ vehicles. It also covers inventory movements: parts going out for a job, returning unused parts, transfers between technicians, etc.

Integrated with FSM Operations:

Field service inventory management doesn’t stand alone – it’s typically a component of Field Service Management (FSM) systems. It ties directly into work orders, maintenance schedules, and customer service.

For example, when a work order is created for a repair, the needed parts should be allocated from inventory. As a technician uses a part on-site, the inventory system should deduct it and possibly trigger restocking. A good FSM inventory system provides real-time visibility of stock levels and usage across all these touchpoints.

Confused by Scattered Stock and Lost Parts?

Learn how structured inventory management keeps your field team efficient and your customers happy.

Common Challenges in Field Service Inventory Management

Even with the clear benefits, managing inventory for field service comes with unique challenges that office-based or retail inventory systems don’t face. Here are some of the key challenges and pain points, and their impact on field service operations:

Distributed Inventory & Lack of Visibility:

In field service, inventory isn’t in one place – it’s spread across warehouses, service vehicles, and sometimes customer sites. Keeping track of parts across multiple locations is difficult if you rely on spreadsheets or manual methods.

Technicians might not know what parts are on another tech’s truck or even in the main stockroom at a given moment. This lack of visibility can lead to duplicate ordering or wasted time calling around to find a needed item.

Inaccurate Records & Shrinkage:

Without a robust system, inventory records can quickly become out of sync with reality. Technicians might forget to report used parts, or paperwork might not be entered until days later.

Items can also get lost or “shrink” without clear accountability. These inaccuracies mean either unexpected stockouts, you thought you had the part, but you don’t, or excess stock(ordering more because records under-report what’s on hand.

Overstocking vs. Stockouts Dilemma:

Striking the right balance is tricky. Field service companies often overcompensate for poor tracking by overstocking every possible part on each truck, leading to bloated inventory costs and wasted shelf (or truck) space.

On the other hand, under-stocking (to save cost) can result in critical parts not being available when needed. This optimization challenge is ongoing: usage patterns change, new product models come out (making old parts obsolete), and it’s difficult to predict what will be needed without good data.

Manual Processes and Inefficiency:

Many small field service operations still handle inventory with pen-and-paper, spreadsheets, or ad-hoc processes. A technician might call the office to ask if a part is in stock, or fill out a form after using a part and turn it in at day’s end.

Manual processes are time-consuming and error-prone. They create delays (e.g., inventory isn’t updated until the end of the week when someone does data entry) and extra work for staff. This also makes real-time decision-making impossible – you don’t know exactly what’s available right now.

Integration Gaps (Siloed Systems):

Inventory management often overlaps with other functions like work order management, purchasing, and billing. If your inventory tracking isn’t integrated with your FSM system or ERP, it leads to double entry and silos. For instance, the service team might use one system to manage jobs, and the warehouse uses another system (or none at all) to manage parts.

This disconnect means field staff lack visibility into inventory, and inventory managers lack context of usage. In a 2023 Service Council survey, 38% of service organizations cited poor integration of parts/inventory data into the service business as a top challenge. Without integration, it’s hard to achieve a seamless flow from inventory to field operations.

Demand Forecasting Uncertainty:

Field service demand can be unpredictable – emergency repair spikes, seasonal surges (e.g., heating parts in winter), or new equipment rollouts can all drive sudden needs for parts. Many companies struggle with inventory forecasting, which parts to stock and in what quantities.

If you base purchasing purely on historical use without accounting for upcoming changes, you may be caught off guard. Conversely, holding inventory “just in case” for every possible scenario isn’t financially viable. Finding data-driven forecasting methods is a challenge, especially without advanced tools.

External Supply Chain Issues:

Field service inventory doesn’t exist in a vacuum – you rely on external suppliers and global supply chains for your parts. Recent years have shown how vulnerable this can be: supplier delays, shipping disruptions, or sudden part shortages can all create inventory shortfalls.

A part that is usually delivered in 2 days might suddenly have a 2-week lead time due to a global shortage. Field service companies then must adapt by stocking critical parts in greater safety quantities, or risk leaving customers waiting. Managing these supply chain fluctuations is an ongoing challenge.

Cost Constraints:

Especially for smaller businesses, budget limitations make it hard to maintain an optimal inventory. Every dollar in inventory is a dollar not spent elsewhere. Field service firms often walk a tightrope between investing in enough stock to be responsive and keeping costs low.

The cost of advanced inventory management tools or software can also be a barrier for some, leading them to stick with inefficient manual methods. However, not investing in inventory management can lead to higher costs in the long run through wasted time and lost business.

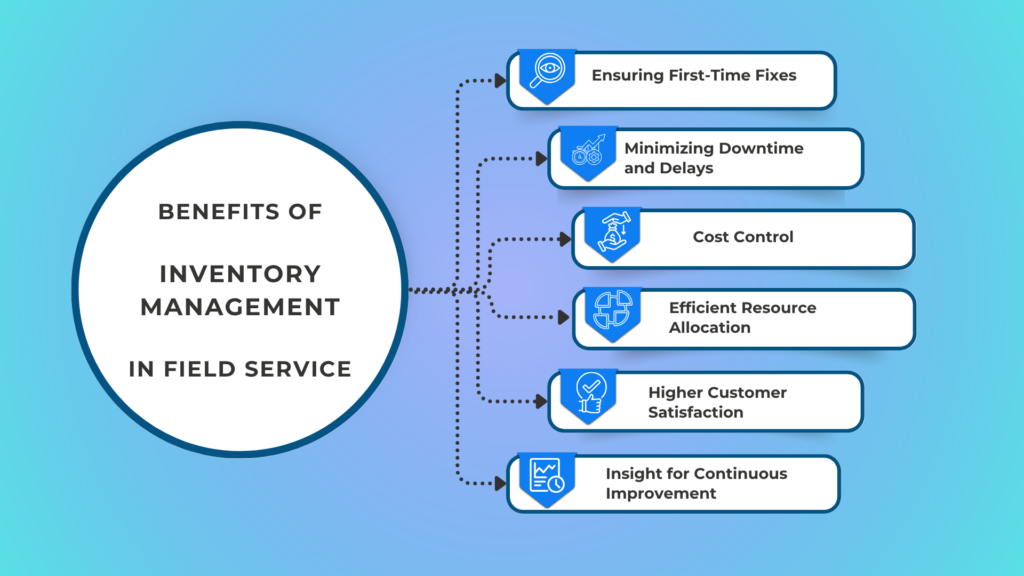

Why Inventory Management is Critical for Field Service (Key Benefits)

Inventory management plays a pivotal role in field service success, but is often underestimated. Before diving into the best tools and strategies, it’s important to understand why it matters and how it directly impacts service performance and customer trust.

Ensuring First-Time Fixes:

One of the most important metrics in field service is the first-time fix rate (FTFR). Every time a technician can’t fix an issue on the first visit due to a missing part, it requires a costly second trip. With effective inventory management, technicians arrive with the right parts on hand, dramatically improving first-time fix rates. Improving FTFR not only boosts customer satisfaction but also saves money, avoiding a second “truck roll” on even 10% of jobs can save tens of thousands of dollars annually.

Minimizing Downtime and Delays:

In industries like HVAC, telecom, or manufacturing equipment service, downtime is expensive. Proper inventory management ensures that critical spare parts are available when equipment breaks down, so repairs happen quickly. This avoids extended downtime for your customers. For the service provider, it means faster response times – no waiting days for a part to arrive. Technicians can complete jobs on the same day, improving service level compliance and customer loyalty.

Cost Control (Avoiding Overstock and Stockouts):

Good inventory management strikes a balance between too little and too much stock. By avoiding overstocking, companies reduce carrying costs (storage, insurance, capital tied up) and obsolete inventory losses. By avoiding stockouts, they reduce expensive emergency part orders and “fire-drills” to cannibalize parts from elsewhere. Optimized inventory means you purchase and hold only what you need based on real demand data. This leads to direct savings and more predictable operational costs.

Efficient Resource Allocation:

With an organized inventory, technicians spend less time searching for parts or driving to pick up items. Instead, they can spend more time doing actual service work. Real-time inventory visibility helps dispatchers and techs allocate resources efficiently. The result is higher productivity and lower idle time for your field team. According to industry research, inefficient inventory processes and searching for parts contribute significantly to non-productive time for techs. Streamlining this through inventory management can boost overall field workforce utilization.

Higher Customer Satisfaction:

Ultimately, inventory management impacts your customers. When field techs arrive prepared and fix issues quickly, customers experience minimal disruption. They don’t have to wait days for a back-ordered part or endure multiple visits. This reliability builds trust and loyalty. In a competitive services market, being known for always having “the right part at the right time” can become a key differentiator that drives positive reviews and repeat business.

Insight for Continuous Improvement:

Effective inventory tracking provides valuable data. Managers can analyze which parts move fastest, what the common repair components are, seasonal demand fluctuations, etc. These insights inform better forecasting and planning. For example, you might discover that a certain spare part consistently runs out in August, indicating a seasonal pattern and prompting you to stock up earlier next year. Data-driven inventory decisions lead to continuous improvement in both cost management and service quality.

Is Your Team Constantly Firefighting Stock Issues?

Identify the hidden gaps that are hurting your field service performance—and how to fix them.

Best Field Service Inventory Management Solution – Microsoft Dynamics 365 Field Service

When it comes to solving these challenges, leveraging technology is key. Field service inventory management software that integrates inventory data with scheduling, work orders, and mobile capabilities can be a game-changer.

Microsoft Dynamics 365 Field Service is a leading end-to-end field service management platform, and it includes powerful inventory management features out of the box. It’s designed for organizations of all sizes, from small service teams to global enterprises.

Key Inventory Management Features to Expect

Dynamics 365 Field Service offers a robust inventory management toolkit. You can track parts across all locations – central warehouses, regional depots, and even down to each technician’s truck stock. The system maintains real-time quantity on hand and detailed transaction histories for every item (purchases, transfers, usage, adjustments).

Key capabilities include:

Inventory Visibility:

A centralized dashboard shows inventory levels by location (warehouse or van). Technicians and managers always know where a needed part is – even if it’s currently on another truck or reserved for a job.

Mobile Access:

Technicians in the field can use the Dynamics 365 Field Service mobile app to check inventory on the fly. For example, if a tech is missing a part, they can quickly search the app to see if a nearby colleague has it in their van. They can also update inventory in real time, which keeps records accurate.

Work Order Integration:

Inventory usage ties directly into work orders. When a technician uses parts on a job and logs them on the work order, the system automatically deducts that quantity from inventory and can even add it to the customer invoice. This ensures billing is accurate and inventory counts stay in sync without extra manual steps.

Automated Reordering:

You can set reorder points/minimum stock levels for important items. As an automated inventory system, Dynamics 365 field service will alert managers or even auto-generate purchase orders when stock falls below the threshold. Moreover, the purchase order management with inventory, so incoming stock is logged and allocated efficiently.

Purchase & Returns Management:

The solution can manage the full lifecycle of parts. It tracks parts from the moment they are purchased (on order), to when they are received into a warehouse, to when they are consumed on a work order, and even if they are returned. These processes are all supported within the software, providing end-to-end visibility.

Analytics & Forecasting:

Being part of the Dynamics 365 ecosystem means robust reporting. Managers can get reports on usage rates, inventory turnover, shrinkage, etc., and even leverage AI insights. Over time, the data in D365 Field Service can help forecast demand for parts more accurately, especially when combined with historical work order data and IoT sensor inputs from connected equipment.

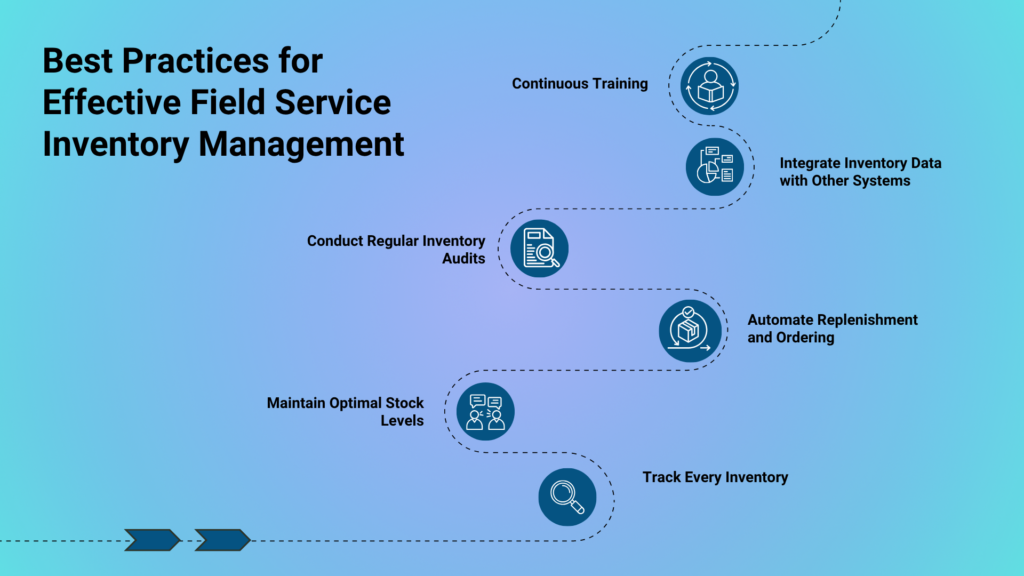

Best Practices and Tips for Effective Field Service Inventory Management

Implementing a great system is one side of the coin; the other is establishing the right processes and habits. Here are actionable best practices to help your field service organization manage inventory more efficiently and accurately, leading to better service and lower costs:

Track and Tag Every Inventory Item:

It’s essential to know what you have and where it is. Tag every part and tool when it enters your inventory, and log it in your system. This sounds tedious, but modern FSM tools make it easier – you can receive items into the system with a quick scan. By tracking each item throughout its lifecycle (from purchase to usage or disposal), you gain complete visibility. This practice eliminates “mystery” losses and lets you trace issues, helping with warranty and compliance.

Maintain Optimal Stock Levels:

Analyze your usage history and set minimum and maximum stock levels for each important item. Use your FSM software’s analytics to identify fast-moving vs slow-moving parts. For critical high-volume parts, keep a safety stock that covers lead time plus a cushion. For slow-moving or expensive parts, consider stocking only a few or none, ordering on demand if possible. Review these levels regularly (quarterly or after a busy season) and adjust based on trends.

Automate Replenishment and Ordering:

Take advantage of automation to reduce manual workload. Configure your inventory system to automatically generate purchase orders or alerts when stock falls below thresholds. For example, if you set a min level of 5 for a certain circuit board and it hits 4, the system could auto-create a PO draft to your supplier for 10 more, pending manager approval. Even if you don’t auto-order, at least have the system send an email alert so nothing slips through the cracks.

Conduct Regular Inventory Audits and Cycle Counts:

Don’t wait for a yearly stocktake to find discrepancies. Implement a routine of cycle counting – small, frequent inventory counts of subsets of items. For instance, each week you might spot-check a different set of parts or one truck’s inventory, comparing the physical count to the system. Regular audits (even mini-audits) will identify if certain items or locations have frequent variances, indicating a process problem or even theft that needs addressing.

Integrate Inventory Data with Other Systems:

Where possible, use integrated systems or sync data between your FSM inventory management and other business software. This might mean your inventory system is part of your FSM platform, or if separate, ensure it’s linked to your ERP/financial system for purchasing and cost tracking. Integration eliminates duplicate data entry and errors – for example, when a part is used on a work order, that usage should flow to inventory and also to your accounting or ERP for job costing.

Continuous Training and Process Improvement:

Make inventory management part of your company culture. Train new hires (both techs and office staff) on the importance of the system and how to use it correctly. Provide refreshers or updates whenever you change a process or the software gets new features, and solicit feedback from the field regularly. Perhaps techs find the mobile app cumbersome in certain scenarios, or the warehouse team notices recurring mistakes on requests. Use this feedback to tweak the process or provide additional guidance.

By implementing these best practices, field service organizations can significantly reduce inventory headaches. You’ll experience fewer “where’s that part?” moments, lower rush shipping bills, and more satisfied customers and technicians.

Want Full Inventory Control without the Chaos?

Discover how to make inventory tracking effortless for your field staff using mobile-first practices.

Manage Your Field Service Inventory Effortlessly with Folio3 Dynamics

In field service, inventory management isn’t just operational—it’s strategic. When parts are tracked, accessible, and aligned with real-time service needs, your technicians perform better, your costs stay under control, and your customers stay satisfied. Effective inventory management is the foundation of high-performing field operations.

At Folio3 Dynamics, we help businesses unlock that potential through tailored implementations of Microsoft Dynamics 365 Field Service. As a certified Microsoft Solutions Partner, we bring deep expertise in transforming disjointed inventory practices into streamlined, data-driven systems.

With our Field Service Inventory Management solutions, you get:

- Centralized tracking across warehouses and mobile stock

- Real-time visibility through technician apps

- Automated reordering and replenishment workflows

- Seamless integration with your ERP and finance systems

- Ongoing support, training, and system optimization

Ready to make inventory your competitive advantage? Partner with Folio3 Dynamics to simplify complexity, reduce waste, and grow your field operations with confidence.