Legacy systems often create silos, leading to poor inventory visibility, delayed order processing, and costly inefficiencies. These challenges can limit growth, reduce profitability, and make it harder to adapt to market demands.

This is where Integrated Warehouse Solutions (IWS) comes into play. IWS refers to the seamless unification of warehouse operations through smart technology, automation, and data-driven processes. It’s not just about managing stock—it’s about optimizing every part of the warehouse ecosystem.

Enter Dynamics 365 Business Central for IWS—Microsoft’s powerful, cloud-based ERP platform tailored to help businesses transform warehouse management. From inventory control to order fulfillment, it empowers you with end-to-end visibility and intelligent automation—all from a single platform.

If you’re wondering “What is Dynamics 365 Business Central for IWS?” or whether it’s the right fit for your business, this guide will walk you through everything you need to know.

Dynamics 365 Business Central for IWS

Dynamics 365 Business Central is Microsoft’s all-in-one, cloud-based ERP solution designed for small to mid-sized businesses. When aligned with Integrated Warehouse Solutions (IWS), it becomes a powerful engine for Business Central warehouse management that provides automation, control, and visibility.

Business Central workflows support IWS functionality right out of the box. Its native capabilities include real-time inventory tracking, logistics management, purchase and sales order processing, and workflow automation—all centralized within a single platform. These features allow warehouse managers and supply chain teams to reduce manual errors, improve efficiency, and respond faster to demand.

For more complex warehouse environments, Business Central also supports integration with WMS (Warehouse Management System) add-ons or built-in advanced warehousing modules. These tools enable additional functionality such as barcode scanning, bin and shelf management, guided put-away, and mobile warehouse access.

In short, Dynamics 365 Business Central for IWS is a future-ready solution that empowers businesses to unify warehouse operations and drive growth through intelligent automation.

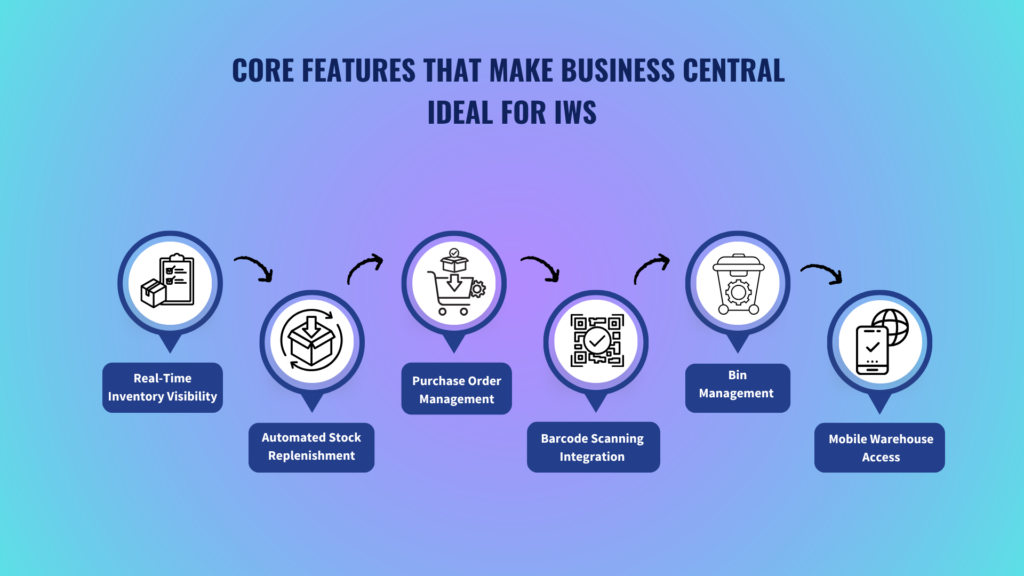

Core Features That Make Business Central Ideal for IWS

Managing a warehouse is no easy task, especially when you’re juggling fluctuating demand, growing order volumes, and pressure to deliver faster than ever. That’s where Business Central for IWS steps in. Designed with warehouse users in mind, it brings all your operations into one smart, streamlined system that works as hard as you do.

Here’s how Business Central for IWS simplifies your day-to-day tasks and helps your warehouse run like a well-oiled machine:

Real-Time Inventory Visibility

Say goodbye to guessing games and stock surprises. With Business Central, you always know exactly what’s in your warehouse, where it’s located, and how fast it’s moving. This real-time insight helps you avoid stockouts, overstocking, and costly delays, giving you the confidence to make quick, informed decisions.

Automated Stock Replenishment

Why wait for stock to run out? Business Central supports complete inventory management by tracking levels and automatically triggers replenishment orders based on pre-set rules like minimum quantities, lead times, or sales trends. That means fewer emergencies, less manual intervention, and more peace of mind.

Purchase Order Management

No more jumping between systems or spreadsheets. With built-in purchase order management, you can create, approve, and track POs in one place. The system even links your purchases directly to sales and inventory, giving you a clear view of your supply chain in motion.

Barcode Scanning Integration

Speed up fulfillment and reduce errors with barcode scanning. Whether you’re receiving goods, picking orders, or counting inventory, Business Central supports barcode hardware and WMS add-ons to streamline every touchpoint in the warehouse.

Bin Management & Smart Put-Away

Not all items belong in the same space. Business Central lets you define warehouse zones, bins, and put-away strategies that guide your team to store products efficiently. It’s like having a GPS for your warehouse.

Mobile Warehouse Access

Why stay tied to a desk? With mobile device integration, your team can work directly from the warehouse floor. From receiving to picking and shipping, everything can be done in real-time using handheld devices or mobile apps, reducing errors and boosting productivity.

These features aren’t just tools—they’re game-changers for any business ready to take warehouse operations to the next level.

Still Using Outdated Systems to Manage Your Warehouse?

Discover how Dynamics 365 Business Central can modernize your operations with real-time data, automation, and CRM insights—all in one platform.

Benefits of Using Dynamics 365 Business Central for IWS

Running a warehouse with disconnected systems or outdated software can feel like trying to drive with the parking brake on. Manual data entry, poor visibility, and delayed processes can lead to costly errors and lost opportunities. So, there are multiple reasons to implement business central and that’s why more businesses are switching to Dynamics 365 Business Central for IWS.

Here’s how Business Central transforms your warehouse operations:

Operational Efficiency

With all your warehouse processes—inventory, purchasing, sales, logistics—working in sync, Business Central eliminates silos and boosts productivity. Tasks that once took hours can now be completed in minutes.

Reduced Manual Errors

Legacy systems often rely on human input at every step, which increases the risk of mistakes. Business Central automates key workflows, reduces data entry, and leverages real-time data to minimize costly errors, such as stock miscounts or incorrect shipments.

Faster Order Fulfillment

Every second counts in today’s fulfillment-driven world. Business Central streamlines picking, packing, and shipping so you can process orders faster and meet customer expectations with ease.

Scalability and Flexibility

As your business grows, so do your operational needs. Business Central scales with you, whether you’re expanding into new locations, adding products, or increasing order volume. You’re never stuck with a rigid system that can’t keep up.

Cloud-Based Access and Real-Time Updates

Forget on-premise limitations. With Business Central’s cloud-based platform, you get real-time access to your warehouse data from anywhere—on the shop floor, in the office, or on the go.

Compared to traditional ERP or outdated WMS systems, Business Central offers a unified, future-ready solution that doesn’t just keep up with your business—it helps drive it forward.

Use Cases / Industry Applications

Dynamics 365 Business Central for IWS isn’t a one-size-fits-all tool—it’s a flexible solution that adapts to the unique needs of different industries. Whether you’re running a manufacturing plant or a fast-paced retail operation, Business Central helps streamline warehouse operations and improve efficiency at every level.

Manufacturing Warehouses

In manufacturing, timing and precision are everything. Business Central supports real-time inventory tracking of raw materials, automated replenishment for production lines, and accurate demand forecasting. For example, a mid-sized electronics manufacturer can use Business Central to manage components, track work-in-progress, and ensure just-in-time delivery to the shop floor.

Retail & eCommerce Fulfillment Centers

Speed and accuracy are critical in retail and e-commerce. Business Central enables fast order picking, barcode scanning, and mobile device access to process high order volumes efficiently. An online fashion retailer, for instance, can use it to manage seasonal stock, automate returns, and update inventory in real-time across multiple warehouses.

Distribution & Wholesale Hubs

For distributors, visibility and logistics coordination are key. Business Central optimizes supply chain flow by offering multi-location inventory control, bin management, and real-time reporting. A wholesale food supplier can track perishable inventory, streamline bulk ordering, and meet strict delivery timelines.

Getting Started with Business Central for IWS: Trial, Setup & Onboarding Made Simple

Curious about the environment setup with Dynamics 365 Business Central for IWS? Whether you’re exploring its features, setting up team access, or onboarding new users, this quick-start guide has you covered. Follow these simple steps to get up and running with zero hassle—and see how Business Central can transform your warehouse operations from day one.

How to Easily Sign Up for a Free Business Central IW Trial Account

- Go to the official Microsoft Dynamics 365 Business Central trial page.

- Click “Start Free” and sign in with a Microsoft work or school email (personal emails like Gmail/Outlook may be restricted).

- Fill in your company details such as name, industry, and size.

- Choose your country/region to ensure localized features.

- Click “Set Up” to provision your trial environment—this may take a few minutes.

- Once complete, you’ll get access to a 30-day free trial of Business Central with IWS capabilities.

Tip: Use a business email linked to Microsoft 365 for a smoother signup process and easier integration with Teams, Outlook, and Power BI.

Key Steps to Set Up Trial Users in Business Central

- Log in to your Business Central Admin Center.

- Navigate to “Users” under the Microsoft 365 admin panel.

- Add trial users by assigning them Business Central licenses (e.g., Team Member, Essentials).

- Go to “User Setup” in Business Central to configure permissions for each user.

- Assign roles like “Warehouse Worker,” “Inventory Manager,” or “Sales Order Processor” depending on user tasks.

- Save changes and notify users to log in using their assigned credentials.

Tip: Ensure users have multi-factor authentication enabled for security.

How Do You Onboard Users?

- Send users a welcome email with login instructions and a link to the Business Central environment.

- Recommend starting with the Role Center dashboard tailored to their function (e.g., Warehouse or Sales).

- Provide access to Microsoft’s in-app training and guided tours.

- Share internal SOPs or walkthrough videos, if available.

- Encourage the use of Microsoft Learn for deeper self-paced learning.

- Assign a team lead or internal champion to support new users during the first week.

Tip: Smooth onboarding = faster productivity. A guided first-day experience can make all the difference.

Want to See Business Central in Action?

Get hands-on experience with a guided trial tailored to your industry—no pressure, just possibilities

Why Choose Business Central Over Other ERP Systems for IWS?

If you’re a small or mid-sized business looking for a warehouse management solution that’s powerful yet practical, Dynamics 365 Business Central for IWS checks all the right boxes. Here’s why:

- Built for SMBs

Unlike many traditional ERPs designed for large enterprises, Business Central offers enterprise-level capabilities without the complexity, perfect for growing businesses. - Seamless Microsoft 365 Integration

Works natively with tools like Outlook, Excel, and Teams—helping your team collaborate and make decisions faster using familiar apps. - Connected with Power Platform

Easily automate tasks with Power Automate, build custom apps with Power Apps, and gain insights with Power BI—all tightly integrated. - Customizable and Scalable

Whether you’re managing a single warehouse or expanding across multiple locations, Business Central grows with your business and adapts to your needs. - Licensing Flexibility

Pay only for what you use. Business Central offers user-based, role-specific licensing, giving you better control over your software investment. - Modern ERP, Simplified

Compared to traditional ERP systems, Business Central is easier to implement, use, and maintain, making it the smarter choice for agile teams.

Why Choose Folio3 Dynamics for Your Business Central IWS & CRM Needs?

At Folio3 Dynamics, we don’t just offer Microsoft Dynamics 365 Business Central—we customize the Business Central experience to fit your industry, your warehouse, and your customer relationships. Whether you’re looking to streamline inventory management or strengthen customer engagement, we help you make the most of Business Central’s ERP and CRM capabilities.

Our offerings include:

- Business Central Implementation for IWS: End-to-end setup tailored for warehouse, retail, manufacturing, and distribution operations.

- CRM Capabilities within Business Central: From managing customer interactions and sales pipelines to tracking service history and follow-ups, we help you unlock the full potential of Business Central as a CRM.

- Custom Integrations & Add-Ons: Connect with third-party WMS systems, Power BI dashboards, and more.

- User Training & Support: We guide your team from trial setup to full-scale adoption with onboarding, training, and ongoing support.

Ready to turn your warehouse into a smarter, customer-focused operation? Let Folio3 Dynamics help you implement the right solution.

Contact us today to explore how Dynamics 365 Business Central for IWS + CRM can transform your business.

FAQs

What is Microsoft Dynamics 365 Business Central used for?

Microsoft Dynamics 365 Business Central is a cloud-based ERP solution designed to help small and mid-sized businesses manage all core operations—like finance, sales, and customer service—through a unified platform. It’s known for offering a complete, all-in-one business management experience.

How much is Dynamics 365 Business Central for nonprofits?

Qualified nonprofit organizations can access Dynamics 365 Business Central at a discounted rate of $28.00 (USD) per user per month, which is 60% less than the standard commercial price

Is Business Central an ERP or CRM?

Business Central is primarily an ERP system, but it also includes built-in CRM capabilities such as customer relationship management and sales tracking.