Technology is the catalyst behind our fast-paced manufacturing industry, goods demanded at one corner of the world are exported to the other end, and the time is short! Manufacturing businesses always juggle multiple processes and depend on disparate systems that slow them down.

What is the challenge? Maintaining efficient operations and simultaneously managing everything from production and inventory to sales and finance.

In such intense circumstances, manufacturers can centralize and simplify their processes with the help of Enterprise Resource Planning (ERP) solutions.

ERP systems are a revolutionary tool for manufacturing companies trying to boost productivity, and data accuracy, and achieve overall growth.

They are not merely another piece of software. In this article, we will have a closer look at how ERP systems can refine production processes, cut down on waste, and keep businesses competitive.

A Growing Market

ERP systems are becoming increasingly important in the business world. According to research by Statista, globally the ERP software market is expected to grow by 3.97% from 2025 to 2029, reaching a massive market volume of $65.29 billion by just 2029.

This exponential growth of the ERP Software showcases the rising demand for modern integrated business management solutions.

Understanding ERP Systems in Manufacturing

Wondering what an ERP is? An ERP system is an all-in-one software solution that connects different parts of a business. It brings together important functions like procurement, production, inventory management, sales, HR, and finance into a single, centralized system.

So instead of getting overwhelmed by juggling multiple software platforms that do not communicate with each other, you can enjoy a single source of information. A system that refines reporting, improves decision-making and makes collaboration a breeze between multiple teams.

ERP systems have become vital in the manufacturing sector.

This is also because processes are naturally complicated. Whether it is supply chain management, monitoring of production schedule, or making sure that customer orders are delivered on time. An integrated platform is necessary for achieving high productivity and growth in the business.

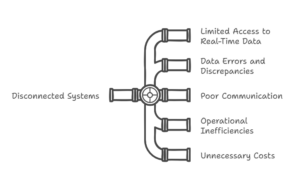

The Problem with Disconnected Systems

1. Limited Access to Real-Time Data

The most common and biggest problem is that manufacturers depending upon separate systems frequently struggle to access real-time data. Important information gets trapped in different departments, and results in delayed and inefficient decision-making.

2. Data Errors and Discrepancies

Businesses run the danger of stock shortages, shipping delays, and unhappy customers when inventory calculations are done incorrectly. These mistakes result in missed deadlines and heavy financial losses.

3. Poor Communication

In the absence of an integrated system, departments rely on manually updating the systems, and this raises the chances of miscommunication. If there is no real-time collaboration then there are confusions and production gets slowed down.

4. Operational Inefficiencies

Production delays are often caused by outdated records of inventory, lost materials, or a lack of supply chain visibility. These inefficiencies in turn affect profitability and cause disruptions in workflows.

5. Unnecessary Costs

Operational costs are high if you are running multiple systems that are disconnected. Extra labor is required to match data across platforms, while inefficiencies in production and inventory management result in financial loss.

To overcome these issues, manufacturers need a solution that encompasses all aspects of their business. And an ERP system is the solution that makes an impact for sure!

How ERP Systems Transform Manufacturing

So how exactly does an ERP System redefine manufacturing? Let us have a deeper look at the myriad of benefits and solutions that it offers:

1. Boosts Productivity

Firstly, an ERP system automates routine tasks that consume your precious time. It rids the employees of all the redundant work that boggs down processes and hence also eliminates manual errors.

Employees spend less time on data entry and more time focusing on activities that will contribute in the long run and add real value to the business.

2. Provides Real-Time Insights

Data is captured and updated instantly in a centralized database. This way manufacturers can instantly access updated and accurate data across departments. This transparency and integrity facilitates faster decision-making and better coordination between teams.

3. Enhances Product Quality

Many ERP solutions come embedded with quality management features that proactively detect possible quality issues before they become worse, track defects, and guarantee compliance with industry standards.

4. Improves Decision-Making

ERP systems provide data-driven insights with the help of advanced reporting and analytics tools. Manufacturers can track production performance, evaluate and analyze trends, and make informed adjustments to maximize efficiency.

5. Optimizes Inventory and Supply Chain Management

Inventory management is a major aspect of any and every business. Manufacturers have real-time visibility into inventory levels, which helps in the efficient management of stock levels and procurement. This results in improved cash flow, reduced waste, and less overstocking.

6. Strengthens Collaboration Between Departments

With all departments having access to the same and updated data, ERP helps eliminate data silos and improves collaboration across all departments. Your teams can work together more efficiently, resulting in improved workflow and faster problem-solving.

7. Enhances Customer Experience

Manufacturers can deliver goods on schedule and give consumers more precise order updates with better inventory tracking and order management. A well-integrated ERP system helps improve customer satisfaction and gains loyalty.

8. Supports Remote and Hybrid Work

Modern ERP solutions come with cloud-based accessibility. This modern development gives employees the flexibility to work from anywhere. This is especially useful in cases where remote monitoring of production or inventory is needed.

Why ERP Is a Must-Have for Manufacturers

The implementation of an ERP system involves much more than just upgrading your technology, rather it is actually about changing the way a company runs.

Manufacturing companies can boost output, cut expenses, and enhance overall performance by getting rid of inefficiencies caused by using disconnected systems.

ERP systems also set you up for future growth. As manufacturing operations scale up, an ERP system makes sure that business processes remain steady, organized, and adaptable to changing demands.

Take the Step Forward

If you are a manufacturer who wants to kick off operational efficiency and stay competitive, then, investing in an ERP system is an intelligent and strategic move. A customized ERP solution can help businesses in the following:

- Improve production and inventory management

- Enhance reporting and oversight of finances

- Make collaboration across teams easy and smooth

- Build stronger customer relationships

- Cut down operational costs and increase profitability

If you are on the lookout for a powerful ERP system that fits your manufacturing needs, now is the perfect time to explore your options. Get in touch with us at folio3 today and unravel the great mystery of how ERP can uplift your business for long-term success and growth!

Final Thoughts…

The manufacturing sector is taking a new face, and businesses that still rely on outdated, fragmented systems will struggle to keep up and might vanish from the sector.

An ERP system brings everything under one roof and gives you smoother operations, enhanced data accuracy, and intelligent decision-making. If you want to secure the future of your manufacturing business, then ERP is your way forward!