Is your automotive organization prepared for the supply chain challenges that have redefined industry dynamics? The sector continues facing challenges with production delays and constrained output. Despite some improvements in 2024, these issues persist and create ripple effects throughout manufacturing operations.

Traditional automotive supply chain management methods simply can’t handle today’s manufacturing complexity. Executives now face the reality of reimagining their operational strategies from the ground up.

The global market for automotive logistics is projected to cross $230 billion in 2025, fueled by rising demand and complex global networks. That growth reflects opportunity, but it also exposes how fragile the auto parts supply chain and vehicle supply chain have become.

In this blog, we’ll explore the biggest challenges of supply chain that have been faced by the automotive industry, along with outlining seven ways modern supply chain solutions are reshaping automotive SCM.

Understanding the Automotive Supply Chain Landscape

The automotive supply chain process has shifted dramatically. What once operated as linear, predictable networks now functions as complex, interconnected ecosystems. These networks span multiple continents and create intricate dependencies that overwhelm traditional management systems.

Modern vehicle supply chain operations involve thousands of components. Each vehicle requires parts from hundreds of suppliers across different geographic regions. This complexity challenges conventional coordination methods.

Contemporary auto supply chain networks face heightened complexity for several reasons:

- Electric Vehicle transitions requiring new supplier relationships

- Regulatory compliance demands across multiple jurisdictions

- Changing consumer preferences driving product variety

- Specialized battery materials and charging infrastructure needs

The transition of electric vehicles is a radical change in the strategy of sourcing of components in automotive. Older models of the car supply chain did not support these new demands. Hence, the operations of the supply chain automotive industry now require an unprecedented level of flexibility to handle just-in-time manufacturing and to maintain strategic inventory levels of important components.

Multi-dimensional networks have emerged in place of the conventional three-tier supplier structure. Also, raw material suppliers, technology partners and logistics providers are now part of the direct relationships. Therefore, the supply chain management of modern automobile industry has to co-ordinate these broadened relationships and at the same time keep the cost competitive and maintain the quality of products and services as well.

How Does Inefficient Supply Chain Management Impact the Automotive Industry?

Production Line Disruptions and Manufacturing Delays

Recent disruptions have caused significant delays in critical component delivery. Microchips remain particularly problematic, creating price peaks due to high demand and low supply. These disruptions cascade through production systems with devastating effects.

Manufacturers face forced assembly line shutdowns and delayed vehicle launches. The semiconductor shortage alone has cost the automotive industry billions in lost revenue. Some manufacturers report production capacity reductions of up to 30% during peak shortage periods.

Manufacturing delays create compounding effects throughout the automotive supply chain:

- Reduced dealer inventory availability

- Declining customer satisfaction scores

- Lost market share to better-prepared competitors

- Unpredictable production schedules that undermine demand fulfillment

Inventory Optimization Failures

Inefficient automotive supply chain management creates a problematic choice between excess inventory carrying costs and stockout situations that halt production. Thousands of components are required to arrive precisely when needed. However, the traditional SCM solutions can’t process this level of coordination requirement. Hence, these inefficiencies result in increased storage costs.

Electric vehicle production intensifies these challenges. Battery components require specialized handling and storage conditions. Poor inventory management of these high-value components leads to significant financial losses from material degradation or obsolescence.

Supplier Relationship Deterioration

Poor automotive industry supply chain management damages relationships with critical suppliers. Without visibility into supplier capacity and performance, manufacturers can’t provide accurate forecasts or collaborate effectively on capacity planning.

These deteriorated relationships become costly during supply shortages. Suppliers prioritize customers with better collaborative relationships and communication systems. Organizations with inefficient supply chain management often find themselves at the bottom of supplier priority lists during allocation decisions.

Quality Control Compromises

Rushed sourcing decisions and inadequate supplier oversight create quality issues that trigger expensive recalls and damage brand reputation. Supply chain disruptions, rising raw material costs, and regulatory compliance issues create pressure to accept substandard components.

Quality compromises in automotive manufacturing carry serious safety implications and regulatory consequences. Also, recall costs can reach hundreds of millions of dollars, far exceeding any savings from poor sourcing decisions.

Financial Performance Degradation

Inefficient supply chain automotive operations directly impact profitability through multiple channels:

- Increased component costs due to poor negotiating position

- Lost sales from production interruptions

- Working capital inefficiencies from inventory imbalances

- Higher total cost of ownership for sourced components

The financial impact extends beyond operational costs. Supply chain inefficiencies signal poor operational management to investors and reduce competitive positioning in an increasingly challenging market environment.

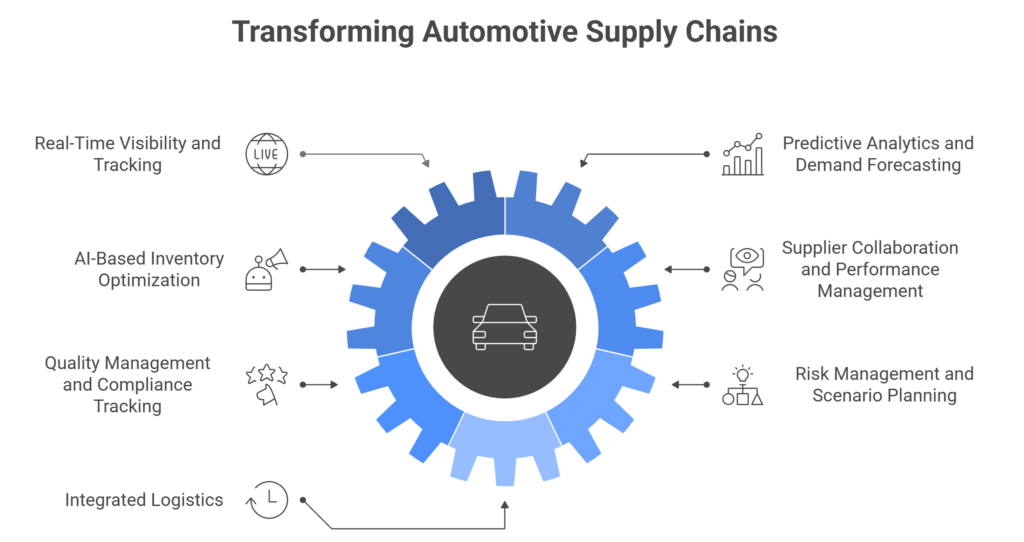

How Modern Solutions Are Transforming the Automotive Supply Chain?

1. Real-Time Visibility and Tracking Systems

Microsoft Dynamics 365 Supply Chain Management delivers end-to-end visibility across automotive supply chain networks through integrated tracking systems. These systems monitor component movement from supplier facilities to production lines with unprecedented detail.

The platform builds supply chain resiliency with real-time visibility and AI-driven insights to mitigate supply chain issues before they impact operations.

Advanced sensor integration and IoT connectivity enable continuous monitoring of:

- Shipment locations and estimated arrival times

- Environmental conditions affecting sensitive components

- Component status throughout the automotive supply chain process

This visibility allows supply chain managers to identify potential disruptions hours or days before they impact production. The system integrates with supplier systems, logistics providers, and manufacturing execution systems. This integration eliminates information silos and provides decision-makers with accurate, real-time data for operational planning and crisis response.

2. Predictive Analytics and Demand Forecasting

Modern supply chain solutions continue strengthening core software features that improve data and convert it into actionable insights. The predictive analytics capabilities of these platforms analyze multiple data sources to generate accurate demand forecasts up to 18 months ahead, which helps the automotive managers in identifying:

- Historical sales and production patterns

- Market trends and economic indicators

- Consumer behavior patterns and preferences

- External factors like regulatory changes

Machine learning algorithms process these vast datasets to optimize automotive industry supply chain management planning. The system continuously refines forecast accuracy by learning from actual demand patterns. Algorithm adjustments occur automatically based on performance feedback. This adaptive approach ensures vehicle supply chain planning remains accurate even as market conditions change rapidly.

3. AI Based Inventory Optimization

Dynamic AI inventory optimization algorithms balance just-in-time efficiency with strategic buffer stock requirements for critical components. The system analyzes component criticality, supplier reliability, and demand variability to determine optimal inventory levels for each part number.

Advanced optimization considers multiple variables simultaneously:

- Carrying costs and storage constraints

- Shortage costs and production impact

- Supplier lead times and reliability metrics

- Production schedule requirements and flexibility

This comprehensive approach ensures auto supply chain operations maintain production continuity while minimizing working capital requirements. The balance becomes dynamic rather than static, adjusting to changing conditions automatically. This automation reduces manual intervention requirements while maintaining optimal inventory balance across the entire car supply chain network.

4. Supplier Collaboration and Performance Management

Integrated supplier portals in Dynamics 365 Supply Chain Management facilitate seamless communication and collaboration between manufacturers and their supplier networks. The platform provides suppliers with real-time access to critical information that enables better decision-making.

Suppliers gain access to:

- Real-time forecasts with confidence intervals

- Production schedules and capacity requirements

- Quality specifications and testing requirements

- Performance metrics and improvement opportunities

Performance management dashboards track supplier metrics including on-time delivery, quality ratings, and cost competitiveness. These metrics enable data-driven supplier relationship management and identify improvement opportunities or necessary relationship adjustments. This collaboration improves automobile industry supply chain management flexibility and reduces the impact of supplier capacity limitations on production schedules.

5. Quality Management and Compliance Tracking

The Warehouse management solution in Dynamics 365 Supply Chain Management provides a rich and flexible set of capabilities. These can be combined and configured to support many warehouse layouts and operational scenarios, including comprehensive quality management processes.

The platform maintains complete traceability records for regulatory compliance and enables rapid issue identification during quality incidents.

Quality management features include:

- Automated inspection scheduling and results tracking

- Supplier certification monitoring and renewal alerts

- Non-conformance tracking and corrective action management

- Statistical process control with trend analysis

Automated quality alerts notify relevant personnel when components fail to meet specifications or when suppliers report quality issues. This rapid notification system enables immediate response to prevent defective components from entering production systems.

6. Risk Management and Scenario Planning

Advanced risk assessment tools analyze potential disruption scenarios and their impact on supply chain automotive industry operations. The system models various risk factors to identify vulnerable supply chain nodes before problems occur.

Risk factors analyzed include:

- Supplier financial stability and credit ratings

- Geographic risks including natural disasters and political instability

- Transportation disruptions and capacity constraints

- Regulatory changes and compliance requirements

These scenario planning capabilities enable supply chain managers to develop contingency plans for various disruption scenarios. The system can automatically activate alternative supplier relationships or transportation routes when predefined risk thresholds are exceeded.

7. Integrated Logistics

Even if production is efficient, poor logistics can stall deliveries and inflate costs. Traditional transportation systems often lack real-time visibility, leading to delays, route inefficiencies, and rising fuel costs.

Dynamics 365 addresses logistics challenges with:

- AI-driven route optimization and shipment tracking.

- Control tower visibility across the full logistics chain.

- Seamless integration with platforms like Uber Freight for dynamic routing.

For example, if a shipment of automotive parts is delayed at customs, the system instantly reroutes orders or reallocates stock to avoid downtime. Logistics managers can view the entire network in real time, ensuring on-time delivery while reducing costs. Integrated logistics transforms the automotive supply chain into a predictable, responsive, and customer-focused system that aligns with global manufacturing demands.

Strategic Approach for Selecting SCM Solutions

A strategic approach is essential when selecting a supply chain management (SCM) solution for the automotive industry. The right platform should not only streamline operations but also enhance resilience, scalability, and adaptability in a constantly changing market.

An effective SCM solution must provide end-to-end visibility across suppliers, plants, logistics partners, and dealerships. This visibility ensures that decision-makers can track real-time performance, identify bottlenecks, and respond quickly to disruptions. Equally important is scalability, the solution should evolve alongside the business as automakers expand into electric vehicles, mobility services, and global markets.

Other critical factors include:

- Predictive insights powered by AI and machine learning to anticipate demand shifts and material shortages.

- Seamless integration with ERP, CRM, IoT, and third-party logistics platforms to create a unified digital ecosystem.

- Compliance and traceability to support ethical sourcing, sustainability goals, and strict automotive regulations.

Microsoft Dynamics 365 Supply Chain Management combines these elements into a single, highly configurable platform. By connecting operations, enabling predictive decision-making, and ensuring global compliance, it transforms automotive supply chains into a source of competitive advantage rather than operational risk.

Conclusion

The automotive industry’s supply chain landscape has changed dramatically. Strategic investment in modern technology solutions that provide real-time visibility, predictive capabilities, and collaborative planning tools has become essential for competitive survival.

Modern solutions like Microsoft Dynamics 365 Supply Chain Management offer comprehensive capabilities that address current industry challenges. These platforms provide the technological foundation necessary for building resilient, efficient automotive supply chain operations that support competitive advantage.

Ready to transform your automotive supply chain operations? Folio3 Dynamics specializes in implementing comprehensive automotive supply chain solutions that drive operational efficiency and competitive advantage. Our proven expertise in Microsoft Dynamics 365 deployment helps automotive organizations achieve measurable improvements in supply chain performance, cost reduction, and operational resilience.

Contact Folio3 Dynamics today to discover how we can accelerate your supply chain transformation and position your organization for sustained success in the competitive automotive marketplace.

FAQs

What technologies are shaping the future of automotive supply chain management?

Emerging technologies such as blockchain, digital twins, IoT sensors, and autonomous logistics are driving efficiency, transparency, and resilience in the automotive supply chain.

How does sustainability impact the automotive supply chain?

Automotive companies are under pressure to adopt sustainable practices, including eco-friendly sourcing, carbon footprint tracking, and circular supply chains to meet regulatory and consumer demands.

What is the role of blockchain in automotive supply chains?

Blockchain ensures transparency and traceability by securely recording transactions across suppliers, manufacturers, and logistics providers, reducing fraud and improving trust.

How are electric vehicles changing the automotive supply chain?

The shift to EVs increases demand for rare materials like lithium and cobalt, introduces new supplier ecosystems, and requires specialized logistics for battery handling and recycling.

What strategies can automotive companies use to mitigate supply chain risks?

Key strategies include diversifying suppliers, nearshoring critical components, investing in digital supply chain platforms, and adopting scenario planning for disruption management.

How does automation improve efficiency in automotive supply chains?

Automation through robotics, AI-driven planning, and smart warehousing reduces errors, accelerates production cycles, and optimizes logistics, creating more agile supply chains.