Growers Express required a proper system through which they can streamline, manage and track information related to areas of:

- Order Management

- EDI

- Warehouse Management

- Inventory Management

- Lot Traceability

Growers Express is a major agricultural company that grows and markets a variety of produce under well-known brands like Green Giant Fresh. Folio3 built an award winning suite of mobile solutions for Growers that were later productized as “Truetrac” – now acquired by FoodLink. These include applications for:

Growers Express required a proper system through which they can streamline, manage and track information related to areas of:

Warehouse Management

Improvement and enhancement in warehouse operations were done in the following areas:

Streamlining of these warehouse operations included:

Enhance WMS functionality by introducing new or utilizing existing locations

To facilitate better and more timely sales decisions in regards to customers that have been allocated Credit Limits, an alert was generated in AX whenever a customer gets critically close to exhausting and/or has exhausted the allocated credit limit.

When the ‘Quantity’ of the SKU is entered in a Sales Lines of a Sales Order, the ‘Net Amount’ on that line gets updated through different processes as below:

(i) For Trade Agreement Orders: Auto-updated and visible on the Sales Line, as is currently.

(ii) When various price parameters are entered manually: Auto-updated and visible on the Sales Line, as is currently.

(iii) When no price parameters are entered: The net amount is calculated and auto-updated at the back-end by taking into account the latest available average price on that day for that particular SKU. Not visible on the Sales Line.

(iv) For a new SKU for which there is no previous price information available, either the latest, or the maximum/average price for the commodity (for eg Lettuce) over the period of the previous 7 days, would be used by the System to calculate the Net Amount.

(b) If and when the dollar amount of ‘AR + Open Orders (including the latest Sales Line that has been updated as elaborated above)’ reaches the Yellow Alert that is designated for that customer, a similar alert as elaborated in FR-4 and Fig 3 above will be generated. The user can close the dialog box/alert and proceed with creation of the Sales Lines.

(c) The System will allow for the Sales Order to be posted if it is in the Yellow status.

In the ‘Credit Status’ column on the ‘Overview’ page of the Sales Order screen shown below, the corresponding cells/fields for Sales Orders that are in yellow or red status should be have a yellow or red ‘fill’ respectively.

For EDI Orders

Based on the parameters elaborated above, if the status of any customer/vendor initiated EDI Order is Red, the System will not allow that Order to be moved out from the virtual staging warehouse 88 and be assigned an actual warehouse. Hence, the Order cannot be proceeded further with till the ‘hold’ is lifted by an authorized person.

Inventory Management

Inventory transfers occur when items are being moved from on location to another. The stages of inventory transfer include:

All transfers are performed by:

Current Process Deployed

To perform a transfer, the operator will use the WMS and perform the following:

From the Transfers page

The quantity entered can be any amount up to the item quantity in the From Location. During the transfer process, items can become reserved to a sales order. If this occurs, an error message will notify the operator that the quantity is not available and cancel the transaction. This would only happen if the item is being transferred from a pickable location. Receiving and Partial Storage locations would be safe from this behavior as they are not pickable locations.

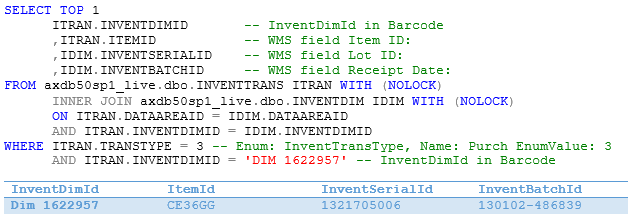

The modification of the pallet label will be completed in house by IT. The modification consists of changing the barcode from the ItemId and InventDimId to the InventDimId only.

It has been determined that the InventDimId is sufficient to lookup the ItemId, InventSerialId and InventBatchId. The WMS barcode transaction will be modified such that the InventDimId is used to perform the lookup.

Sample SQL code to determine the ItemId and Inventory dimensions based on the InventDimId.