Supply chain risk management is no longer about optimizing for cost; it’s about anticipating and neutralizing existential threats. Global logistics networks are currently defined by persistent volatility, from geopolitical tensions and trade policy shifts to extreme weather and financial instability.

In this environment of relentless uncertainty, the margin for error is shrinking, and the financial consequences of supply chain failure are immense. Research indicates that companies can lose up to 42% of a year’s EBITDA due to a single major disruption in the supply chain. This immense exposure underscores the critical strategic mandate on your desk: transition your organization from reacting to shocks to proactively mitigating them.It is perhaps why 71% of CEOs are already planning to adjust their supply chain operations to counter current economic and trade policy risks.

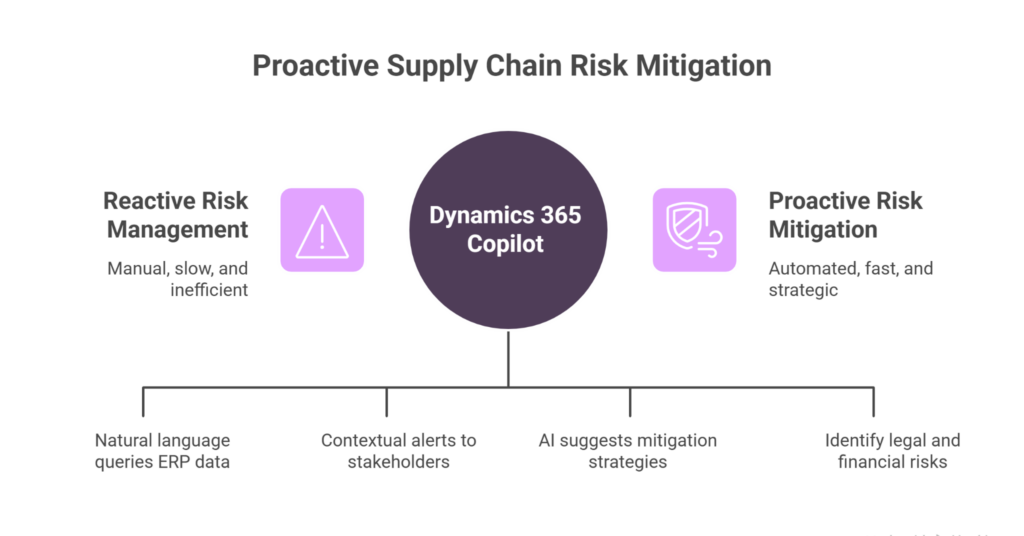

This transformation demands a new class of technology. It requires a system that can look beyond your internal ERP data and synthesize intelligence from the entire global ecosystem. In this blog, you will discover how Dynamics 365 Copilot Supply Chain Risk Management moves your organization beyond internal failure analysis to deliver true Proactive Risk Management, leveraging Generative AI for predictive insights, optimizing sourcing decisions, and securing quantifiable Supply Chain Resilience.

The Dynamics 365 Foundation: Where Traditional Risk Assessment Ends

Before embracing generative AI, it is crucial to understand the inherent limitations of traditional Enterprise Resource Planning (ERP) systems in handling external risk.

Dynamics 365 Supply Chain Management provides foundational capabilities, such as the Supply risk assessment workspace. These tools are highly effective at providing a robust internal health check. They measure past supply delivery performance, using structured internal data like On-Time In-Full (OTIF) ratings for suppliers and products. Based on planned purchase orders, the system then projects a risk assessment for future goods, quantifying the quantity and amount at risk if past performance trends persist.

While this structured approach provides excellent visibility into operational vulnerabilities and supplier reliability, its power is inherently limited to “Reactive Prediction.” It tells you the risk of future failure based on internal history.

What it historically missed was a holistic assessment of external vendor risks that originate from unstructured factors. This includes real-time financial ratings, security compliance issues, or, most critically, large-scale, sudden disruptions triggered by geopolitical turmoil, severe weather events, or major labor disputes.

The traditional system is adept at calculating the financial exposure if Supplier X continues to be 10% late. It is, however, functionally blind to the sudden, external headline, such as a major port closure that will cause that late rate to jump to 80% tomorrow. This need for constant, real-time external intelligence is the critical void filled by the integration of Dynamics 365 Copilot Supply Chain Risk Management.

Generative AI as Your Global Sensing System: The Core of Proactive Risk Management

The strategic leap provided by Dynamics 365 Copilot Supply Chain Risk Management is its ability to fuse your private, structured ERP data with real-time, unstructured external intelligence. This fusion creates a truly predictive and context-aware risk model.

Fusing Internal and External Intelligence

Dynamics 365 Copilot utilizes advanced Generative AI features, including Large Language Models (LLMs) and Azure AI services, operationalized within the unified Microsoft Supply Chain Center.

The key mechanism for Proactive Risk Management is constant, automated data crawling. Copilot actively monitors the external environment, pulling up-to-the-minute intelligence from sources related to:

- Geopolitics: Monitoring news feeds for sanctions, political instability, and trade policy changes that may impact key sourcing locations.

- Weather: Tracking severe weather events (hurricanes, floods, droughts) that could immediately halt carrier networks or factory operations.

- Financials: Detecting shifts in supplier credit ratings or localized economic crises that foreshadow financial instability.

This process combines your internal operational risk score (derived from D365 SCM data) with an external environmental risk score (derived from the AI’s analysis of global feeds).This results in a comprehensive, real-time predictive model for every tier of your supply network.

Instant Traceability

Copilot’s intelligence goes beyond merely flagging a risk; it translates that external risk into immediate, measurable internal impact. This is the crucial step that accelerates your response timeline.

When Copilot identifies an external event (e.g., a port closure or a new tariff), its predictive insights instantly surface impacted orders across multiple critical categories:

- Materials and inventory levels.

- Carrier and distribution networks.

- Specific purchase orders and planned supply.

By instantaneously connecting a global event to specific internal purchase orders and inventory, the AI bypasses the traditional hours or days required for manual data correlation and investigation, enabling up to 40% faster decision-making speed in supply chain operations.

The Four Pillars of Proactive Supply Chain Risk Mitigation with Dynamics 365 Copilot

The true ROI of Copilot Dynamics 365 Supply Chain Risk Management is realized in its capacity to automate and accelerate the mitigation workflow, allowing your strategic teams to focus on resolution rather than detection and communication.

Pillar 1: Accelerated Assessment via Natural Language

The generative AI capability dramatically simplifies the interaction with complex ERP data. Instead of running complex reports, managers use a conversational chat experience to ask precise, natural language questions:

“Trace all inbound shipments of Component X from Supplier Y affected by the current severe weather event in Southeast Asia”.

This dramatically speeds up the initial assessment phase, empowering even non-technical users to query and summarize vast datasets that previously required specialized technical expertise. Furthermore, Copilot streamlines the procurement process by assisting buyers in rapidly assessing the impact and risk associated with high volumes of changes to confirmed purchase orders.

Pillar 2: Automated Communication and Execution

This capability represents a significant win for operational efficiency. Once a risk is detected and the impacted orders are surfaced, Copilot automatically drafts a contextual alert or message to notify affected internal stakeholders, partners, or suppliers.

- Contextual Messaging: The message, generated using services like Azure OpenAI, is tailored to the specific disruption (e.g., a rail strike) and lists the precise purchase order numbers and requested actions.

- Instant Dispatch: The supply chain manager simply reviews and approves the professionally drafted alert, saving critical time on manual communication and ensuring time-sensitive information is dispatched instantly.

This shift eliminates the dull, menial, and transactional work of data gathering and communication, allowing your planners to focus solely on high-impact strategic alternatives.

Pillar 3: Intelligent Inventory Optimization and Sourcing Recommendations

Proactive risk management extends directly into inventory and distribution planning. Copilot moves beyond alerts by suggesting viable mitigation strategies based on real-time inventory and capacity.

- Optimal Fulfillment: It can recommend re-routing strategies, such as fulfilling high-priority customer orders via an alternate distribution center to ensure timely delivery.

- Alternative Sourcing: For procurement, Copilot monitors global events and supplier performance to suggest alternative sourcing options.

By leveraging AI-Powered Demand Forecasting, which analyzes historical sales, market trends, seasonality, and external data, Copilot helps your inventory managers optimize stock levels across the network, recommending precise replenishment actions based on live data and predictive alerts.

Pillar 4: Strategic Contract Gap Analysis (Beyond Logistics)

Risk mitigation isn’t confined to movement of goods; it also impacts legal and financial exposure. Through integration with tools like Copilot Studio, Dynamics 365 Copilot Supply Chain Risk Management provides advanced Supplier Relationship Management (SRM) functionality.

Managers can identify potential legal or financial gaps and risks in new purchasing agreements by automatically comparing the new contract against standard organizational templates. This proactive contractual analysis is instrumental in avoiding long-term legal and financial risks before a high-stakes agreement is executed.

How Dynamics 365 Copilot Tackles Five Critical Supply Chain Risks?

The real measure of a resilient system is its capability to solve specific, high-impact risks that challenge C-suite priorities. Dynamics 365 Copilot Supply Chain Risk Management provides targeted solutions for both internal operational threats and external global volatility.

|

Critical Supply Chain Risk |

The Challenge |

Copilot’s Proactive Solution |

|

Geopolitical and Weather Disruption Risk |

Global instability, trade policy changes, or sudden severe weather events creating unforeseen supply halts. |

Real-Time External Risk Sensing: Copilot constantly monitors global events (geography, weather, financials) to proactively detect issues. It instantly traces the impact of a confirmed external event onto specific internal purchase orders and inventory, allowing managers to anticipate delays hours or days in advance. |

|

Demand Volatility and Forecasting Error |

Relying on historical data alone, leading to highly inaccurate forecasts, which results in stockouts or costly overstock. |

AI-Powered Demand Forecasting: Copilot analyzes complex correlations across large datasets, including historical sales, market trends, seasonality, and newly integrated external data to predict demand with unmatched accuracy. This reduces the percentage error rate in prediction. |

|

Supplier Performance and Reliability Risk |

Inbound shipments are delayed or incomplete due to poor supplier performance, leading to production halts. |

Proactive Supplier Risk Management & Sourcing Optimization: The system monitors past supplier delivery performance (e.g., OTIF rates) and fuses this internal data with external global event monitoring. If a high-risk vendor is flagged, Copilot suggests alternative sourcing decisions and replenishment actions based on live capacity data. |

|

Contractual and Procurement Risk |

New purchasing agreements containing financial or legal gaps, or the slow, manual review process delaying critical sourcing. |

Strategic Procurement Risk Analysis: Copilot Studio integration allows the AI to automatically identify potential legal or financial gaps and risks in new purchasing agreements by comparing them against standard organizational templates before execution. It also helps buyers rapidly assess the impact of changes to confirmed purchase orders. |

|

Operational Downtime and Maintenance Risk |

Unexpected failures of critical factory machinery or equipment, leading to expensive, unscheduled production downtime. |

Improved Equipment Reliability via Predictive Maintenance: Intelligent systems process data, often from IoT devices in smart factories, to identify malfunctions and breakdowns in their early stages or predict them before they happen, allowing for dynamic adjustments to production schedules and minimizing associated financial losses. |

Quantifying Resilience: The Measurable ROI of AI in SCM

The strategic investment in Dynamics 365 Copilot Supply Chain Risk Management must be justified by measurable improvements in resilience, efficiency, and financial health.

By delivering predictive planning and reduced disruptions, Copilot ensures organizations stay ahead of demand shifts, achieving a significant competitive advantage.

|

Measurable Impacts on Key Performance Indicators (KPIs) |

||

|

Supply Chain KPI |

Pre-Copilot Baseline Risk |

Copilot/AI Mitigation Impact (source: Microsoft) |

|

Stockouts/Shortages |

High risk due to inaccurate forecasting and late detection of supplier issues. |

Documented reduction in stockouts of up to 32%. |

|

Decision-Making Speed |

Delayed by manual data correlation and report generation. |

Up to 40% faster decision-making speed in supply chain operations. |

|

Forecasting Accuracy |

Significant error rate due to reliance on static, historical data. |

Improved accuracy; objective to reduce forecasting error rate by 10%. |

|

Order Fulfillment Speed |

Constrained by reactive planning and slow, manual communication. |

An 18% increase in order fulfillment speed. |

|

Operational Downtime |

High risk from unexpected equipment failure. |

Improved equipment reliability by anticipating malfunctions. |

Conclusion: Resilient Growth Through Predictive Power

Dynamics 365 Copilot Supply Chain Risk Management represents the essential strategic investment for organizations aiming to thrive in an era of persistent volatility. The integration of Generative AI ensures that you are constantly monitoring the global pulse, enabling instant impact analysis, optimizing sourcing decisions, and automating the communication required for timely mitigation. By empowering your teams with this level of predictive insights, your organization can stop managing the supply chain in the rear-view mirror and start future-proofing its operations for resilient, sustainable growth.

Ready to transform your supply chain risk management? Folio3 Dynamics specializes in implementing Dynamics 365 Supply Chain Management with Copilot integration. Our team provides end-to-end support from strategy development through deployment and optimization, ensuring you realize measurable value from your investment.

Contact us today to discuss how Dynamics 365 Copilot can strengthen your supply chain resilience.

FAQs

Q1: How will AI / Copilot impact supply chain roles and jobs?

AI will automate tedious, repetitive tasks like demand forecasting, order tracking, and inventory updates, freeing humans to focus on strategic decision-making. But roles requiring relationships, supplier negotiation, and judgment under uncertainty will still need human skills.

Q2: Can AI really predict unexpected external disruptions (weather, geopolitics)?

AI systems like Copilot can continuously monitor external news, weather reports, and financial signals to flag emerging threats, then map them back to internal orders and inventory. This gives you early warning on risks you wouldn’t catch using internal ERP data alone.

Q3: How does AI help with vendor / supplier risk management?

AI can track supplier financial health, delivery performance, and external events, then predict which vendors are at risk. This lets procurement pivot early, e.g. substituting or dual sourcing before major failures occur.

Q4: How soon can a company realistically adopt Copilot-driven proactive risk management?

It depends on data maturity, systems integration, and infrastructure, but many firms can begin in phases, starting with demand forecasting or supplier monitoring, and scale into full proactive risk workflows over 12–24 months.

Q5: What should you ask vendors / auditors when evaluating AI in vendor risk management?

Ask how the AI model is hosted, whether it’s retrained on client data, fallback/rollback plans if outputs go wrong, control over prompt injection, and whether “human in the loop” validation is enforced.