The manufacturing landscape is defined by constant volatility, where geopolitical shifts, and strained supply chains develop uncertainty in workflows. The traditional practice of relying on static historical data, fragmented reports, and manual spreadsheets for forecasting is no longer viable.

The challenge for manufacturing leaders today is clear: how to integrate real-time intelligence into planning without increasing the complexity of their technology stack. The answer lies in generative AI.

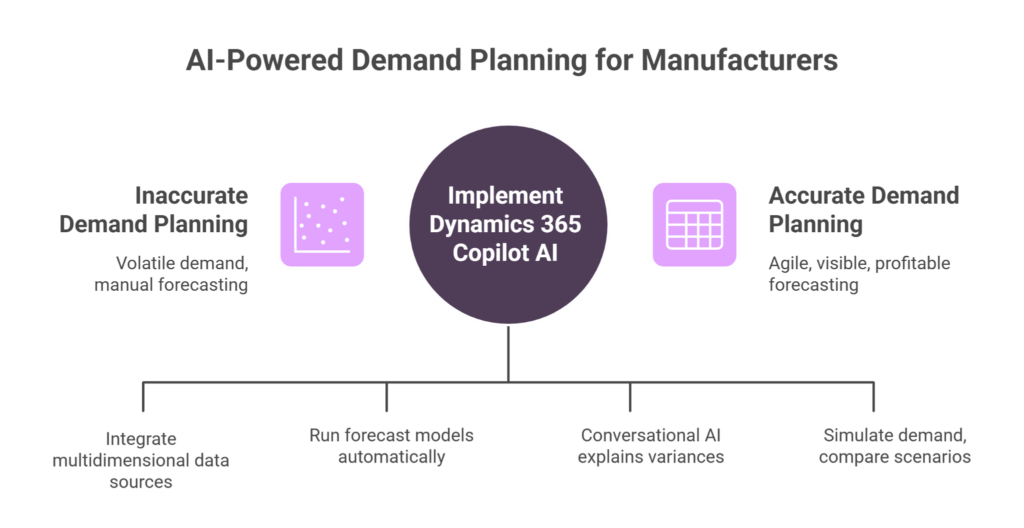

This is where Dynamics 365 Copilot AI steps in. Integrated directly into Microsoft Dynamics 365 Supply Chain Management (SCM), Copilot represents Microsoft’s powerful generative AI tool that is transforming demand planning and forecasting. It acts as the intelligent bridge that connects historical data, market agility, and human expertise, enabling planning teams to transition from reactive data processors to proactive, strategic decision-makers.

In this comprehensive guide, we will explore the critical necessity of AI demand planning, detail the core capabilities of Copilot within a manufacturing workflow, showcase real-world impact, and provide criteria for choosing the best demand planning software with AI support.

Why Manufacturers Need AI-Driven Demand Planning

Manufacturers operate in a high-stakes environment where demand volatility is the norm. The pressure points are numerous, ranging from managing long, complicated lead times for specialized components to navigating highly fluctuating consumer demand and persistent supply uncertainty.

Common manufacturing challenges in demand planning include:

- Data Fragmentation: Information is often siloed across legacy systems (CRM, ERP, spreadsheets), leading to an incomplete view of true demand signals.

- Slow Reaction Time: Manual spreadsheet-based models are slow to adapt to sudden market shifts, such as economic changes, geopolitical factors, or sudden spikes in competitor activity.

- The New Product Problem: Introducing new products or expanding into nascent markets leaves planners with no historical data, making traditional forecasting methods almost impossible.

These limitations mean that traditional statistical models often fall short, resulting in significant forecast errors, planning too low leads to lost sales, while planning too high results in excess inventory and high carrying costs.

What Is Dynamics 365 Copilot AI and How It Transforms Demand Planning

Dynamics 365 Copilot AI is Microsoft’s generative AI assistant, built natively into the Dynamics 365 Supply Chain Management Demand Planning workspace. It is designed to be a conversational partner for the planner, helping them diagnose the why behind a forecast variance or trend.

A Powerful, Conversational AI Layer

The platform acts as an intelligent layer that leverages Microsoft’s robust, ai powered demand planning software architecture. This architecture utilizes sophisticated algorithms like ARIMA, ETS, and PROPHET, which generate deep time series analyses. Instead of requiring the planner to interpret complex statistical deviation charts, Copilot translates these outputs into clear, natural language summaries.

The core transformation hinges on four pre-defined analytical capabilities that directly address common causes of demand volatility:

|

Core Capability |

Manufacturer’s Benefit |

Technical Function |

| Shift Detection | Compares demand between two consecutive periods (e.g., this month vs. last month) | Proactive Response: Quickly identifies abrupt, recent changes demanding immediate material procurement or capacity rescheduling. |

| Trend Analysis | Evaluates emerging or declining patterns across six consecutive periods of time series data. | Strategic Planning: Confirms long-term patterns, guiding product lifecycle management or promotional campaign timing. |

| Outlier/Anomaly Detection | Pinpoints unusual values, such as single large, one-off orders or data entry errors. | Data Cleanliness: Flags data errors or one-time events, preventing them from disproportionately distorting the next forecast. |

| Deviation Analysis | Compares two distinct time series (e.g., Forecast vs. Actual Sales, or Scenario A vs. Scenario B). | Continuous Refinement: Measures forecast accuracy against real performance, enabling rapid model tuning and override validation. |

By instantly isolating whether a forecast issue is due to a sudden shift or a long-term trend, Dynamics 365 Copilot AI moves the planner beyond simply knowing what the number is to understanding why the number exists.

Responsible AI and Trust

For manufacturing leaders, trust in technology is paramount. Microsoft addresses this through its Responsible AI framework, ensuring AI demand planning tools operate with security, privacy, and compliance. Copilot provides the top ten most significant findings per query, guaranteeing that planners must review and validate the most critical insights before committing to decisions.

How Manufacturers Use Dynamics 365 Copilot AI for Forecasting

Integrating Dynamics 365 Copilot AI for manufacturers involves a guided, collaborative workflow that combines robust data processing with human expertise. This structure ensures that forecasts are not just statistically accurate but are also validated by institutional knowledge. Below is the step-by-step walkthrough

Data Ingestion and Preparation

The workflow begins with the ingestion of comprehensive, multidimensional data, including sales history, Bills of Material (BOM), production capacity data, and external market drivers. The demand planning environment in D365 SCM manages this data flow seamlessly.

Copilot Model Training and Forecast Generation

Dynamics 365 SCM automatically runs forecast models (ARIMA, ETS, etc.) or leverages custom Azure Machine Learning models. The resulting forecast is immediately integrated into the Demand Planning worksheet.

Planner Review with AI Suggestions

Instead of manually comparing dozens of charts, the planner uses Copilot’s conversational AI. A planner can ask in natural language, “Explain the forecast variance for SKU-X in the Western Region,” and Copilot instantly returns a summary of the most significant shifts or outliers detected, respecting all applied filters.

Scenario Comparison and Publishing

Planners use the tools for demand planning within D365 SCM to perform “What-If” analysis, for example, simulating a 15% rise in demand or a doubling of supplier lead times. Copilot’s Deviation Analysis then rapidly compares the scenario forecast against the baseline forecast, highlighting discrepancies in plain language. Once validated, the forecast is published to Material Requirements Planning (MRP) and Production modules.

This process shifts the planner’s focus from statistical interpretation to strategic execution. The capability to use AI demand planning to manage variant-level forecasting, a crucial task for discrete manufacturers, is greatly simplified by Copilot’s ability to analyze data within precise, filtered contexts.

Real-World Use Cases: Where AI Demand Planning Delivers Impact

The integration of demand planning and forecasting with generative AI leads to measurable improvements in accuracy, inventory, and agility across various manufacturing verticals. This is where strategic demand planning techniques deliver tangible ROI.

Example 1: Automotive Parts Manufacturer Reducing Excess Inventory

Automotive and component manufacturers often deal with immense SKU complexity and highly volatile demand driven by service and recall schedules. Using AI for demand planning, a parts manufacturer can leverage Copilot’s Anomaly and Shift Detection to filter out one-off “bulk” orders and identify sudden, sustained changes in regional demand.

This precision allows them to adjust safety stock levels for slow-moving, high-cost parts, directly leading to a significant reduction in excess inventory carrying costs while maintaining service levels. Furthermore, the internal sales department at Poloplast, a discrete manufacturer, reported a “big efficiency gain” in customer service simply because employees could consult D365 directly for real-time item availability.

Example 2: Consumer Electronics Improving New Product Launch Forecasts

New product introductions (NPIs) are notoriously challenging because historical data is non-existent. A consumer electronics company can utilize Copilot’s scenario simulation capabilities by modeling assumptions for an NPI based on similar product categories and planned promotional lifts. By comparing multiple time series, such as projected demand, revenue, and profit, and running ‘what-if’ analyses, planners can build confidence in their numbers. This enables manufacturers to forecast uplift during sales events and ensure sufficient stock is available across multiple sales channels, minimizing the costly stockouts that can damage a launch’s reputation.

Integrating Copilot with Existing Systems

The power of Dynamics 365 Copilot AI for manufacturing is amplified by its native and seamless integration across the Microsoft ecosystem. This is critical for demand planning solutions where data flow integrity is paramount.

Copilot is not a standalone add-on; it is an integrated feature of Dynamics 365 Supply Chain Management. This ensures that the insights generated flow effortlessly between all connected modules:

- Finance: Accurate forecasts translate directly into reliable budgeting and revenue projections.

- MRP/Planning Optimization: The final, validated forecast is seamlessly fed into the Material Requirements Planning (MRP) engine and Planning Optimization, ensuring materials are ordered and capacity is reserved precisely when needed.

- Production: Forecasts drive operational efficiency by informing detailed production scheduling and maintenance planning.

Redefining the Future of Demand Planning for Manufacturers!

The era of manual, reactive forecasting is over. Dynamics 365 Copilot AI for manufacturers provides the essential, transformative tool required to survive and thrive in today’s volatile global economy. By shifting the planning cycle from days to hours, ensuring forecasts are driven by multi-dimensional insights, and empowering planners with explainable, conversational intelligence, manufacturers gain better agility through rapid response to market shifts, increased visibility via clear natural language data summaries, and ultimately higher profitability through optimized inventory and reduced costs.

Ready to revolutionize your demand planning with conversational AI? Partner with Folio3, a certified Microsoft Dynamics expert, to implement Dynamics 365 Copilot AI tailored to your manufacturing needs. Let’s turn your forecasting challenges into a competitive advantage.

FAQs

How does Copilot support demand plan analysis in Dynamics 365 Supply Chain Management?

Copilot allows planners to ask predefined questions and receive summaries that identify key shifts, trends, anomalies or accuracy issues within filtered demand-plan data.

What types of analytical patterns can Copilot detect in demand-planning workflows?

It can analyze shifts (two consecutive periods), trends (six periods), deviations (comparing two time-series) and anomalies.

What limitations should planners be aware of when using Copilot’s demand-planning insights?

Copilot returns up to ten ranked insights only, and results from non-English languages may be less accurate. Also, human review is required before acting.

What best practices help ensure responsible use of Copilot in demand planning?

Ensure proper data governance, review AI-generated summaries against actual plan data, and maintain human-in-the-loop decision-making.

How does Copilot respect filtering and context in demand-planning analysis?

When users apply filters (for example by region, product or time-period), Copilot analyzes only the selected subset and reflects those parameters in its insights.

Is Copilot’s demand-planning capability supported across multiple languages and how was it evaluated?

Yes, Copilot’s demand-planning capability works in all languages that Demand Planning supports as of early 2025. Non-English versions may show slightly lower accuracy. The team evaluated the system through user feedback and real-world testing.