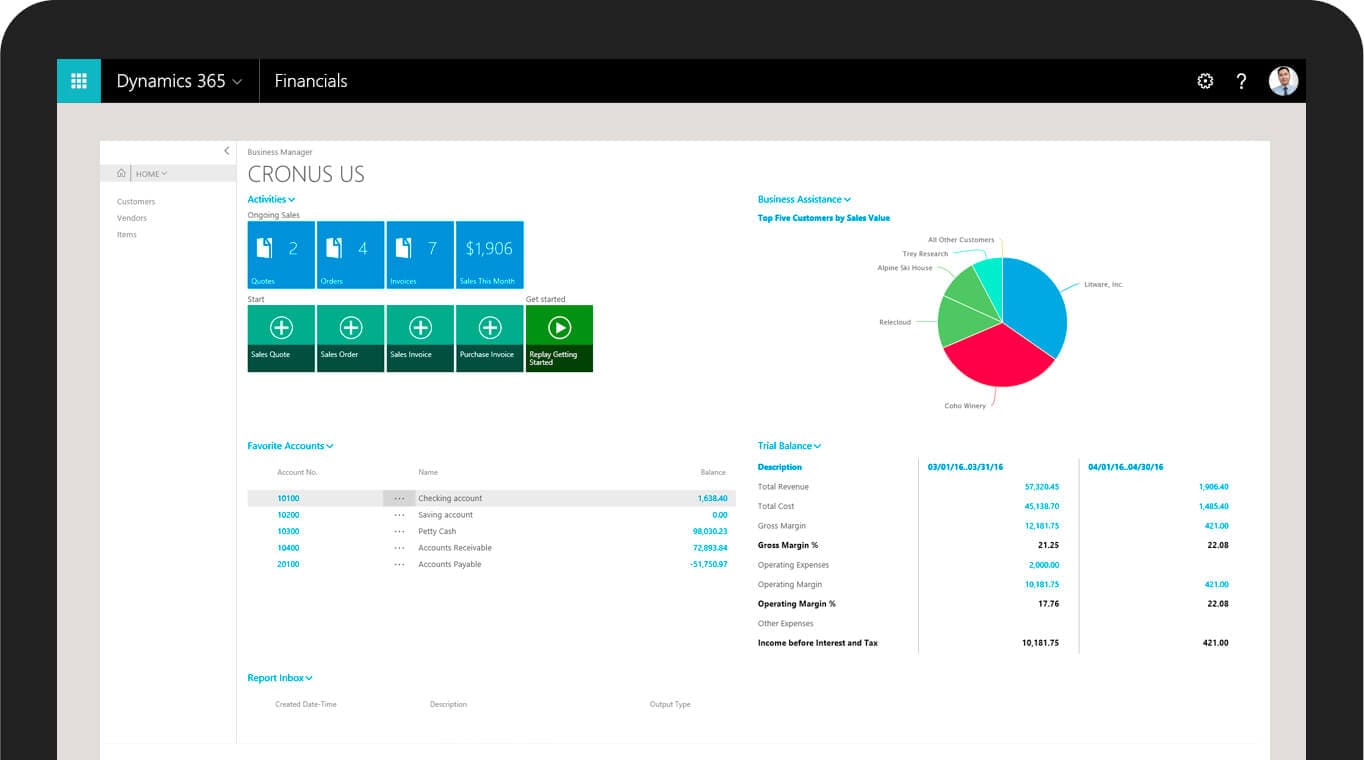

In this post we’ll take a closer look at inventory management in Dynamics AX 2012 or automated inventory movement. As you know the typical flow of inventory (depicted below) involves inventory traveling through the distribution center in a manually directed fashion, either through warehouse operations, manual compilation of inventory data, or via the manual execution of some specific reports in an ERP.

These inventory movement operations can be of several types such as:

- Receiving

- Cooling / Icing

- Put-away to bulk storage

- Put-away to partial reserves

- Replenishment of case pick

- Removal from case pick to partial reserves

- Pallet consolidation

- Inventory dump / donation, etc.

Manual inventory operations however can be time consuming and inefficient. And since timely movement of inventory is critical in a high volume high turnover warehouse environment, having automated processes in place for handling inventory movement operations are absolutely vital. Since by having automated processes in place for inventory management, you can reduce the time it takes for inventory to reach a pick-able location and provide better service to your customers.

Additionally, if inventory movement is automated, it eliminates the need for running reports and examining complicated data, in order for making time sensitive decisions, since the automated processes in place will move items to where they’re needed, without human intervention.

So what’s the ideal high level design for automating inventory management in Dynamics AX, within, out of, or across warehouses? At a high level, automation within the distribution center can be achieved by a series of system directed algorithms or Directives. These are typically three types of directives:

- Put-Away

- Periodic

- Triggered

Put-Away Directive

Once the inventory has arrived and has cooled, it needs to be stored at an appropriate location by the Put-away operator. What we can do to automate this process is, have the Dynamics AX system automatically suggest the appropriate location for the inventory (when it’s scanned in the system by the put-away operator), rather than having the operator move the inventory to a location of his own choosing, which may not the best choice for storage if the inventory needs to moved out quickly. This automatic location suggestion by Dynamics AX will be determined based on the Put-Away Directives configured in the system.

Periodic Directive

Once the inventory is stored it may need to be moved to another location based on the picking needs, or aging of the inventory. This process too can be automated by having batch jobs in place that will generate transfer journals in Dynamics AX 2012, based on the implemented algorithms behind each batch job as periodic directives.

These Dynamics AX 2012 batch jobs can be scheduled on periodic basis as per the business’ needs, so you can analyze and initiate the transfer process by creating the Transfer journals and assigning them to the Transfer/Put-away operators.

Triggered Directive

This directive can be best understood by example. Let’s suppose that the last item of inventory has been picked from a particular location, such that the system determines that there should be 0 quantity of this item left in this location, and the system generates a prompt (known as a “Pick to Vanish” prompt) asking the picker if there is no more inventory in that location. If the picker responds “Yes” then the system safely assumes that the inventory is accurate in that location. If the picker responds as “No” then the system assumes that the inventory count is not accurate at that particular location. For each successful inventory clean operation, the system can then generate a profit/loss journal in Dynamics AX 2012 as a result of this directive.

Inventory Management in Dynamics AX 2012 (Technical Implementation Guidelines)

For implementing Inventory Movement Automation in Dynamics AX you can use the standard modular approach whereby you simply plug in new directive algorithms as new ones are developed. You can start with a set of basic core algorithms (directives) that plug into an algorithm/directive manager, and you should be able to turn these directives on and off as needed. These Directives will control the overall inventory movement operations via a standard inventory journal and transactions. The system design should be scalable so that it can cater for future expansion, as the business grows.

About Folio3 Dynamics Services

FDS (Folio3 Dynamics Services) is a dedicated division of Folio3 that specializes in Microsoft Dynamics AX, Dynamics CRM, Dynamics NAV and Dynamics GP based development, customization and integration services. Our main focus is on Enterprise Mobility. We firmly believe that opening up Microsoft Dynamics AX and other products to iOS Android, Windows 8 and Windows Phone users will have a huge impact on organizational agility and productivity.