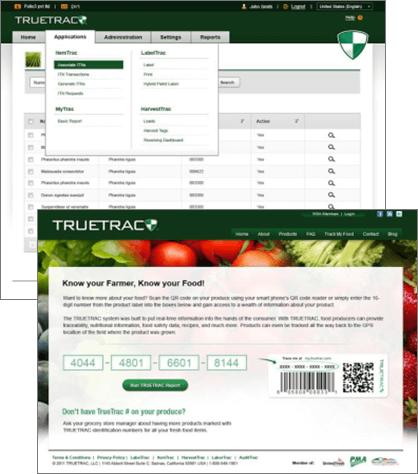

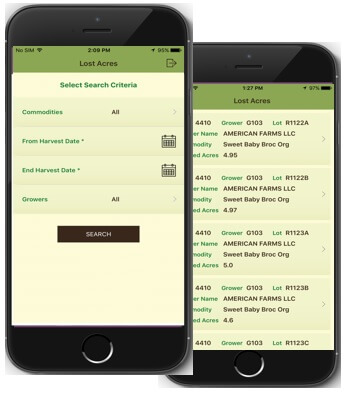

Growers Express is a major agricultural company that grows and markets a variety of produce under well-known brands like Green Giant Fresh. Folio3 built an award winning suite of mobile solutions for Growers that were later productized as “Truetrac” – now acquired by FoodLink. These include applications for.

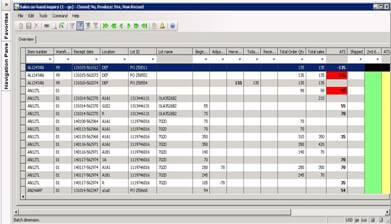

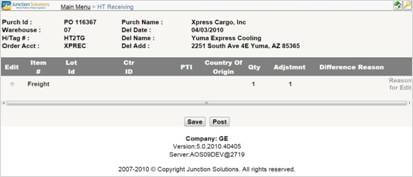

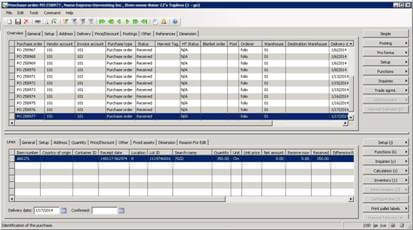

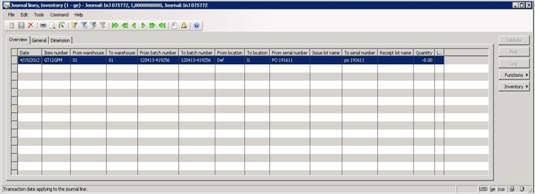

- Food safety and produce traceability

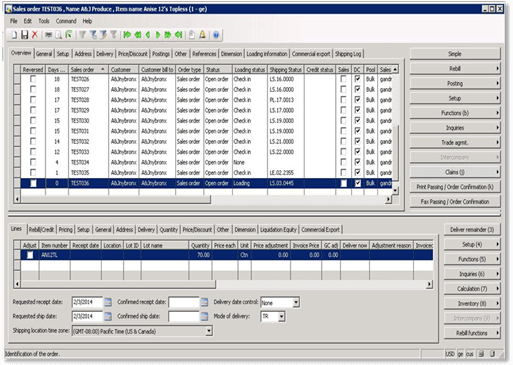

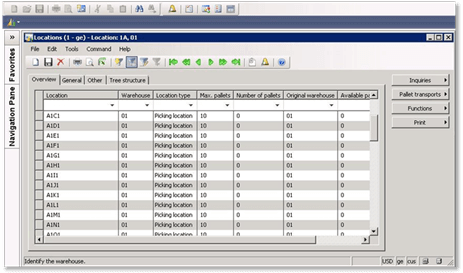

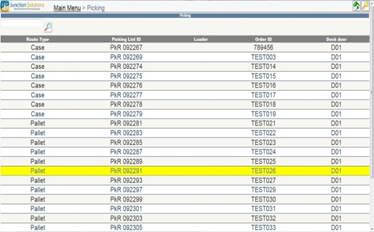

- Inventory management

- Label printing in the field

- Payroll information capture in the field

- Crop planning

- Mobile surveys